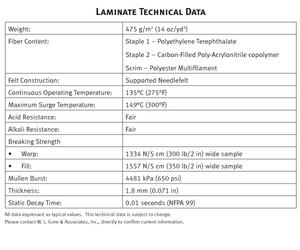

Data Sheet: Polyester Felt, Anti-Static GORE? Filter Bag 475 g/m2 (14 oz/yd2)

Data Sheets, 英語

A 135°C (275°F) maximum service temperature, anti-static polyester felt filter bag for use in pulse-jet style dust collectors where static dissipation is required.

Features and Benefits

- Patented GORE? High Durability membrane technology provides an excellent combination of filtration efficiency, airflow, and durability

- Polyester fibers provide good all-around chemical resistance, especially in applications operated below 79°C (175°F)

- Special multifilament scrim design provides excellent dimensional stability and resistance to mechanical damage over the life of the filter

- Carbon-filled poly-acrylonitrile co-polymer fibers provide static dissipation (passes NFPA-99 Laminate Static Decay Test)

Applications

- Chemicals processing: dryer baghouses, bin vents, and nuisance dust collectors in the pigment, plastic, and catalyst industries

- Minerals processing: coal mill collectors

- Metals processing: process-venting and material-handling dust collectors for pulverized coal

- Power generation and Incineration: coal-handling collectors and coal-milling baghouses

Technical Specifications

|

Fiber content |

Staple 1 – Polyethylene Terephthalate |

|

Felt construction |

Supported needlefelt |

|

Continuous operating temperature |

135°C (275°F) |

|

Maximum surge temperature |

149°C (300°F) |

|

Acid resistance |

Fair |

|

Alkali resistance |

Fair |

|

Weight |

475 g/m2 (14 oz/yd2) |

|

Breaking strength |

|

|

- Warp |

1334 N/5 cm (300 lb/2 in) wide sample |

|

- Fill |

1557 N/5 cm (350 lb/2 in) wide sample |

|

Mullen burst: |

4481 kPa (650 psi) |

|

Thickness |

1.8 mm (0.071 in) |

|

Static decay time |

0.01 seconds (NFPA 99) |

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.